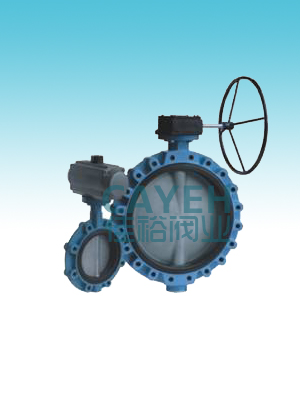

CYD71 FULL LUG TYPE BUTTERFLY VALVE

Applicable standards:

Flange connection:ANSI 150 LBS DIN2501-PN10 JIS10K

Design:EN 593 GB/T 12238

Application area:Chemical and petrochemical industry..

Food industry.

Pharmaceutical and cosmetic industry.

Paper industry.

Shipbuiding sector.

Nuclear, hydroelectric and thermoelectric power stations.

Water treatment and distribution.

Gas distribution

Lron and steel industry,etc.

Temperature range:-10℃ to 160℃(different materials could bring/cause some changes)

Face to Face:GB/T 12221 J1

ISO 5752 Short,series 20

BS5155 Wafer Short/Medium

DIN3202 Part3,series K1

Top Flange:ISO 5211

Body:Ductile Iron、Cast carbon steel、Stainless steel、Aluminium alloy

Disc:Ductile Iron、Cast carbon steel、Stainless steel、Aluminium alloy

Shaft:Stainless steel

Seat:EPDM、NBR、VITON、PTFE

Valve Actuation:Lever、Gear、Pneumatic、Electirc

Leakage class:RATEA EN 12266-2(Zero leakage)

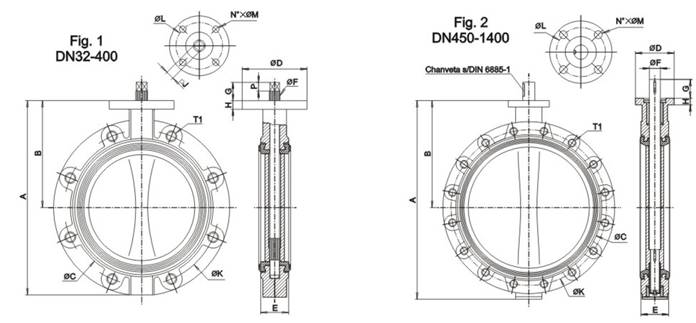

Dimensions data

| PN10 | PN16 | ANSI150 | ||||||||||||||||||

| VALVES DIMENSIONS | K | TALADROS | K | TALADROS | K | TALADROS | ||||||||||||||

| ROSCADOS | ROSCADOS | ROSCADOS | ||||||||||||||||||

| DN | A | B | C | D | E | F | G | H | J | L | N°×M | P | PESO | THREADED | THREADED | THREADED | ||||

| MM | " | WEIGHT | HOLES | HOLES | HOLES | |||||||||||||||

| N°×T1 | N°×T1 | N°×T1 | ||||||||||||||||||

| FIG.1 DN32-400 | ||||||||||||||||||||

| 32 | 1-1/4” | 206 | 140 | 82 | 88 | 33 | 10.5 | 30 | 24 | 8 | 70 | 4×9 | 17 | 2 | 110 | 4×18 | 110 | 4×18 | 98.5 | 4×1/2” |

| 40 | 1-1/2” | 206 | 140 | 82 | 88 | 33 | 10.5 | 30 | 24 | 8 | 70 | 4×9 | 17 | 2 | 110 | 4×18 | 110 | 4×18 | 98.5 | 4×1/2” |

| 50 | 2” | 226 | 156 | 103 | 88 | 43 | 10.5 | 30 | 24 | 8 | 70 | 4×9 | 17 | 3.5 | 125 | 4×18 | 125 | 4×18 | 120.6 | 8×5/8” |

| 65 | 2-1/2” | 246 | 161 | 117 | 88 | 46 | 14.5 | 30 | 24 | 9 | 70 | 4×9 | 17 | 4.5 | 145 | 4×18 | 145 | 4×18 | 139.7 | 8×5/8” |

| 80 | 3” | 259 | 169 | 134 | 88 | 46 | 16.5 | 30 | 24 | 11 | 70 | 4×9 | 17 | 5 | 160 | 4×18 | 160 | 4×18 | 152.4 | 8×5/8” |

| 100 | 4” | 295 | 187 | 153 | 88 | 52 | 16.5 | 30 | 24 | 11 | 70 | 4×9 | 17 | 6.5 | 180 | 4×18 | 180 | 4×18 | 190.5 | 8×5/8” |

| 125 | 5” | 335 | 206 | 182 | 105 | 56 | 18.5 | 30 | 24 | 14 | 70 | 4×9 | 17 | 8 | 210 | 4×18 | 210 | 4×18 | 215.9 | 8×3/4” |

| 150 | 6” | 352 | 215 | 209 | 105 | 56 | 18.5 | 30 | 24 | 14 | 70 | 4×9 | 17 | 9 | 240 | 4×23 | 240 | 4×23 | 241.3 | 8×3/4” |

| 200 | 8” | 422 | 255 | 270 | 105 | 60 | 22.5 | 30 | 24 | 17 | 70 | 4×9 | 17 | 15 | 295 | 4×23 | 295 | 4×23 | 298.5 | 8×3/4” |

| 250 | 10” | 460 | 265 | 320 | 150 | 68 | 25.5 | 40 | 20 | 19 | 102 | 4×11 | 20 | 21.5 | 350 | 4×23 | 355 | 4×27 | 362 | 12×7/8” |

| 300 | 12” | 523 | 280 | 374 | 150 | 78 | 30.5 | 40 | 20 | 22 | 102 | 4×11 | 20 | 30 | 400 | 4×23 | 410 | 4×27 | 431.8 | 12×7/8” |

| 350 | 14” | 570 | 300 | 426 | 170 | 78 | 30.5 | 40 | 20 | 22 | 140 | 4×11 | 20 | 39 | 460 | 4×23 | 470 | 4×27 | 476.3 | 12×1” |

| 400 | 16” | 644 | 340 | 486 | 170 | 102 | 35.5 | 40 | 20 | 27 | 140 | 4×11 | 20 | 52 | 515 | 4×27 | 525 | 4×30 | 539.8 | 16×1” |

| FIG.1 DN450-1400 | ||||||||||||||||||||

| 450 | 18” | 737 | 390 | 538 | 175 | 114 | 50 | 80 | 25 | - | 140 | 4×18 | - | 87 | 565 | 4×M24 | 585 | 4×M27 | 577.9 | 4×1-1/8” |

| 500 | 20” | 825 | 440 | 593 | 175 | 127 | 50 | 80 | 25 | - | 140 | 4×18 | - | 117 | 620 | 4×M24 | 650 | 4×M30 | 635 | 4×1-1/8” |

| 600 | 24” | 965 | 507 | 695 | 250 | 154 | 60 | 90 | 30 | - | 165 | 4×22 | - | 177 | 725 | 4×M27 | 770 | 4×M33 | 749.3 | 4×1-1/4” |

| 700 | 28” | 1100 | 575 | 795 | 300 | 165 | 60 | 90 | 30 | - | 254 | 8×18 | - | 258 | 840 | 4×M27 | 840 | 4×M33 | 863 | 4×1-1/4” |

| 750 | 30” | 1150 | 600 | 860 | 300 | 190 | 65 | 110 | 30 | - | 254 | 8×18 | - | 296 | 900 | 4×M30 | 900 | 4×M33 | 914 | 4×1-1/4” |

| 800 | 32” | 1248 | 655 | 911 | 300 | 190 | 65 | 110 | 30 | - | 254 | 8×18 | - | 330 | 950 | 4×M30 | 950 | 4×M36 | 978 | 4×1-1/2” |

| 900 | 36” | 1325 | 685 | 1010 | 300 | 203 | 80 | 110 | 30 | - | 254 | 8×18 | - | 505 | 1050 | 4×M30 | 1050 | 4×M36 | 1086 | 4×1-1/2” |

| 1000 | 40” | 1457 | 754 | 1124 | 300 | 216 | 80 | 110 | 30 | - | 254 | 8×18 | - | 661 | 1160 | 4×M33 | 1170 | 4×M39 | 1200 | 4×1-1/2” |

| 1100 | 44” | 1580 | 815 | 1220 | 300 | 216 | 80 | 110 | 30 | - | 254 | 8×18 | - | 840 | 1270 | 4×M33 | 1270 | 4×M39 | 1314 | 4×1-1/2” |

| 1200 | 48” | 1721 | 873 | 1324 | 300 | 254 | 100 | 110 | 35 | - | 254 | 8×18 | - | 1020 | 1380 | 4×M36 | 1390 | 4×M45 | 1422 | 4×1-1/2” |

| 1300 | 52” | 1910 | 1005 | 1460 | 350 | 360 | 120 | 120 | 35 | - | 298 | 8×22 | - | 1650 | - | - | - | - | 1537 | 4×1-3/4” |

| 1400 | 56” | 1990 | 1025 | 1530 | 350 | 360 | 120 | 120 | 35 | - | 298 | 8×22 | - | 1900 | 1590 | 4×M39 | 1590 | 4×M45 | 1651 | 4×1-3/4” |

LEVER OPERATOR VALVE SERIES

LEVER OPERATOR VALVE SERIES